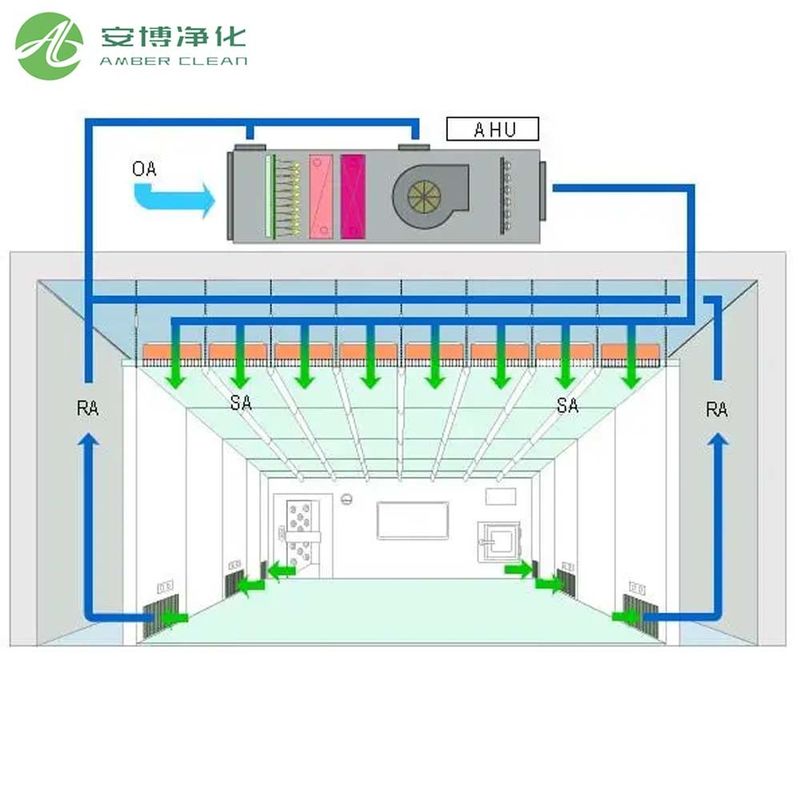

O sistema de tratamento de ar é o elemento mais essencial do controlo ambiental na construção de salas limpas e salas de operações modulares.Unidade de tratamento de arO nível de limpeza do espaço (AHU) determina não só o nível de limpeza desse espaço, mas também o consumo de energia, a estabilidade no funcionamento do equipamento e a experiência do utilizador.

O que são as Unidades de Tratamento de Ar?

O que são as Unidades de Manuseio de Ar?A sua missão é garantir a qualidade do ar, temperatura e umidade, e estabilidade do fluxo de ar, ajudando o espaço a manter o nível de limpeza especificado a longo prazo.

Em salas de operações modulares e laboratórios de alta qualidade, as AHU não só fornecem ar limpo, mas também funcionam em conjunto com equipamentos de purificação, como filtros HEPA, FFU,e chuveiros de ar para garantir um ambiente estéril e seguro.

Projeto de economia de energia: reduzir o consumo de energia, melhorar a eficiência

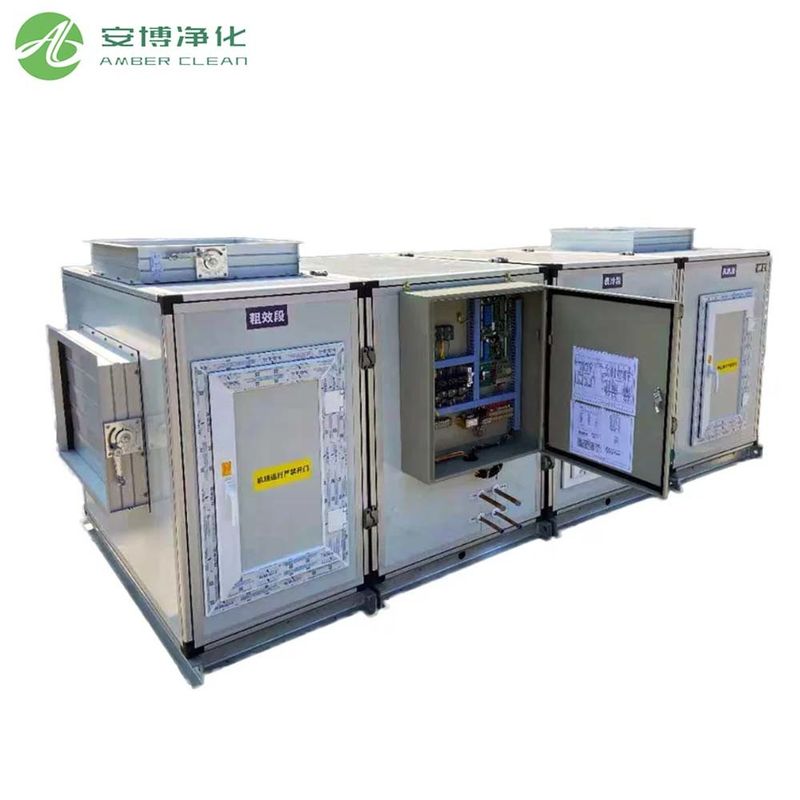

A utilização de unidades de tratamento de ar (AHU) de poupança de energia está gradualmente a tornar-se a unidade de escolha em diferentes projectos de salas limpas.Nossos AHUs têm design aerodinâmico otimizado e ventiladores de alta eficiência de frequência variável com sistemas de controle inteligentesTambém escalonam o volume de ar e o consumo de energia de acordo com a carga real, e os custos operacionais resultantes a longo prazo são muito reduzidos.

A concepção modular das unidades facilita a manutenção e a expansão, assegurando a solução de tratamento de ar adequada para diferentes classes de salas limpas (classe 10010000).

Unidade de tratamento de ar

O controlo preciso da temperatura e da humidade é crucial em muitas aplicações industriais.ou bobinas de água quente para responder rapidamente às demandas de temperatura ambiente, garantindo o conforto dos ocupantes e a estabilidade do processo.

Para laboratórios, salas de operação hospitalares e ambientes de processamento de alimentos,A temperatura e a umidade estáveis não são apenas cruciais para a eficiência da produção, mas também afetam diretamente a qualidade e a segurança dos produtosAtravés de sensores inteligentes e lógica de controlo automático, as unidades permitem ajustes em tempo real, criando um ambiente de sala limpa confiável para os nossos clientes.

Cenários de aplicação típicos

- Salas de operações modulares

- Fabricas de alimentos e cosméticos

Por que escolher-nos?

- Mais de 17 anos de experiência no setor: Desde a consultoria de design até a instalação e comissionamento, fornecemos soluções de sala limpa completa para clientes em todo o mundo.

- Personalizável: Projetamos o sistema AHU ideal com base no tamanho do espaço, nível de sala limpa e requisitos da indústria.

- Serviço completo: Fornecemos desenhos profissionais de design, instalação no local, orientação técnica e serviço pós-venda.

- Qualidade confiável: Usamos materiais de alta qualidade e rigoroso controle de qualidade para garantir um funcionamento estável e uma longa vida.

Com mais de 17 anos de experiência na indústria, fornecemos soluções eficientes e de economia de energia para atender às exigências rigorosas de indústrias como farmacêutica, eletrônica,alimentaçãoSe também estiver interessado nos nossos produtos, por favor,Contacte-nosPara mais detalhes.

Perguntas frequentes

Q1:Sou novo em projetos de salas limpas e não sei muito sobre AHUs.

A:As unidades de tratamento de ar (AHU) são equipamentos básicos utilizados para controlar a qualidade do ar interior, temperatura e umidade.e umidificação para garantir que as salas limpas e as salas de operações modulares cumpram os níveis de limpeza especificados.

P2:Porque é que os AHUs precisam de aquecimento?

A:Em muitas salas limpas ou laboratórios, as flutuações de temperatura podem afetar a estabilidade do processo e a qualidade do produto.ou bobinas de água quente para manter uma temperatura constante, assegurando um ar confortável, estável e seguro na sala de operações ou no laboratório.

P3:Porque não usamos um ar condicionado convencional?

A:Os condicionadores de ar convencionais só ajustam a temperatura e a umidade, enquanto um AHU fornece filtragem de ar, controlo de limpeza,e gestão precisa do fluxo de ar para atender aos níveis de limpeza da classe 100 à classe 10000Além disso, pode trabalhar em colaboração com filtros HEPA, chuveiros de ar, FFU e outros equipamentos para garantir que o ambiente da sala limpa atenda aos padrões da indústria.

Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!  Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!